NaOH dosing unit include NaOH dosing pump, NaOH Alternative tank as well as a pH sensor. Dosing pump frequency is controlled through PLC to maintain the inlet water pH on alkaline aspect (i.

Similarly, utilizing a additional stringent type of water, when not demanded, could cause amplified costs. Incorporate during the amplified scrutiny with the at any time-altering regulatory landscape, it gets much more significant to own a whole understanding of the water a method necessitates.

Through your inspection, figure out the source of the water used for moist granulations or for almost any aqueous liquid preparations in addition to to the laboratory. It ought to be of USP purified water quality both chemically and microbiologically.

SMBS dosing device encompass SMBS dosing pump, SMBS Option tank and an ORP sensor. In advance of water enters in to RO membranes it is vital that every one oxidizing agents from water must be take out. SMBS is cutting down agent which gets rid of chlorine which can be still left right after softener.

Fairly lessen temperatures could also be satisfactory, presented the business has suitable data to demonstrate that a reduced temperature operates as intended. If WFI is held at ambient temperature as an alternative to recirculation at elevated temperature, it should be dumped or diverted to non-WFI use 24 hours after being generated.

The water used in pharmaceutical production should fulfill stringent standards to make sure the safety and efficacy of pharmaceutical goods.

Consumers will not be obligated to hire precise and perhaps archaically generated types of analytical water where solutions with equivalent or better good quality, availability, or analytical performance may possibly exist. The consistency and trustworthiness for manufacturing these different analytical waters need to be confirmed as manufacturing the specified attributes. Also, any alternate analytical water have to be evaluated on an application-by-application basis from the consumer to be certain its suitability. Following is really a summary of the different types of nonmonographed analytical waters which are cited within the USP&#one hundred fifty;NF. Distilled Water— This water is produced by vaporizing liquid water and condensing it in a very purer condition. It's used mainly like a solvent for reagent preparation, but It's also laid out in the execution of other facets of checks, for example for rinsing an analyte, transferring a examination content for a slurry, for a calibration standard or analytical blank, and for exam equipment cleansing. It is additionally cited since the commencing water to be used for building Superior Purity Water. Because none of the cited uses of this water suggest a necessity for a selected purity attribute which will only be derived by distillation, water meeting the necessities for Purified Water derived by other means of purification may be equally suitable wherever Distilled Water is specified. Freshly Distilled Water— Also known as “a short while ago distilled water”, it's manufactured in the same fashion to Distilled Water and will be used Soon following its generation. This suggests the need to avoid endotoxin contamination in addition to every other adventitious forms of contamination with the air or containers that could arise with prolonged storage. It really is used for getting ready remedies for subcutaneous take a look at animal injections along with for your reagent solvent in checks for which there appears to be no significantly significant water purity wanted which could be ascribable to becoming “freshly distilled”. During the “exam-animal” use, the expression “freshly distilled” and its screening use imply a chemical, endotoxin, and microbiological purity that might be equally content by Water for Injection (however no reference is made to those chemical, endotoxin, or microbial characteristics or specific defense from recontamination).

utilizes elements which can be extremely effective deionizers and that do not lead copper ions or organics into the water, assuring a really superior quality water. When the water of the purity contacts the environment even briefly as it is being used or drawn from its purification method, its conductivity get more info will quickly degrade, by up to about one.0 µS/cm, as atmospheric carbon dioxide dissolves from the water and equilibrates to bicarbonate ions. Therefore, In case the analytical use necessitates that water purity continues to be as superior as you possibly can, its use must be protected against atmospheric publicity. This water is used to be a reagent, to be a solvent for reagent preparation, and for test apparatus cleaning wherever a lot less pure waters would not carry out acceptably. Even so, if a consumer's routinely out there purified water is filtered and fulfills or exceeds the conductivity requirements of Higher Purity Water, it may be used in lieu of Higher Purity Water. Ammonia-Cost-free Water— Functionally, this water will need to have a negligible ammonia focus to stop interference in assessments sensitive to ammonia. It's been equated with Significant Purity Water that has a substantially tighter Stage one conductivity specification than Purified Water because of the latter's allowance for just a minimum degree of ammonium among other ions. On the other hand, If your consumer's Purified Water were filtered and satisfied or exceeded the conductivity specifications of High Purity Water, it could incorporate negligible ammonia or other ions and will be used in lieu of Superior Purity Water. Carbon Dioxide-Free Water— The introductory portion of the Reagents, Indicators, and Alternatives area defines this water as Purified Water that's been vigorously boiled for at least 5 minutes, then cooled and protected against absorption of atmospheric carbon dioxide. As the absorption of carbon dioxide has a tendency to drive down the water pH, most of the works by using of Carbon Dioxide-Cost-free Water are possibly connected for a solvent types of water used in pharmaceuticals in pH-related or pH-delicate determinations or as a solvent in carbonate-sensitive reagents or determinations. One more use of the water is for specified optical rotation and coloration and clarity of solution tests. Nevertheless it is feasible that this water is indicated for these assessments simply because of its purity, It's also attainable the pH outcomes of carbon dioxide containing water could interfere with the outcomes of those exams. A 3rd plausible reason that this water is indicated is usually that outgassing air bubbles may interfere with these photometric-type assessments. The boiled water preparing technique may also enormously decreased the concentrations of a number of other dissolved gases in addition to carbon dioxide. Thus, in some of the purposes for Carbon Dioxide-Free Water, it could be the inadvertent deaeration result that truly renders this water acceptable.

Confocal method was used to analyze the morphology with the cells. Cells on picked places have been picked out, as well as corresponding profiles analyzed Using the SensoSCAN software five.

A further state of affairs to become prevented may be the establishment of an arbitrarily significant and frequently nonperformance dependent action stage. These kinds of unrealistic action degrees deprive consumers of meaningful indicator values that can induce remedial technique routine maintenance.

Manufacture of pharmaceutical water employs sequential device operations (processing measures) that tackle particular water high-quality attributes and guard the operation of subsequent cure measures. An average analysis course of action to pick an proper water high-quality for a selected pharmaceutical function is proven in the choice tree in Determine 2. This diagram can be used to help in defining needs for precise water uses As well as in the selection of device functions. The final unit Procedure used to make Water for Injection is limited to distillation or other procedures equal or exceptional to distillation while in the removing of chemical impurities as well as microorganisms and their parts. Distillation has an extended background of reputable efficiency and can be validated as being a unit Procedure for the creation of Water for Injection, but other technologies or combos of systems might be validated as staying equivalently efficient. Other technologies, for instance ultrafiltration pursuing other chemical purification method, could possibly be ideal in the creation of Water for Injection if they are often shown through validation for being as successful and dependable as distillation. The arrival of new products for older systems, which include reverse osmosis and ultrafiltration, that let intermittent or ongoing operation at elevated, microbial temperatures, display assure for a valid use in manufacturing Water for Injection.

The analyses with the mobile height shown a slight reduction of your values in comparison With all the Manage cells, appropriate Using the distribute and elongation on the migration cells. Major variances (p < 0.05) with regard Regulate cells have been found. No considerable variances amongst peak values at the two different cell densities ended up uncovered. Regarding volume values, discrete changes have been detected. No sizeable distinctions ended up uncovered (neither among Manage cells nor involving unique cells densities).

It is recognized, however, that other mixtures of media and incubation time and temperature could from time to time or even regularly result in higher figures of colony-forming units remaining observed and/or distinct species being recovered.

The requirements for biopharmaceutical water and steam are exacting. And that's why each individual facet of your plant style and design is investigated, analyzed and made to your... View Products

Edward Furlong Then & Now!

Edward Furlong Then & Now! Daniel Stern Then & Now!

Daniel Stern Then & Now! Jurnee Smollett Then & Now!

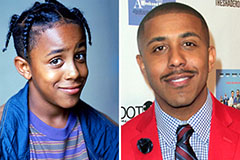

Jurnee Smollett Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now!